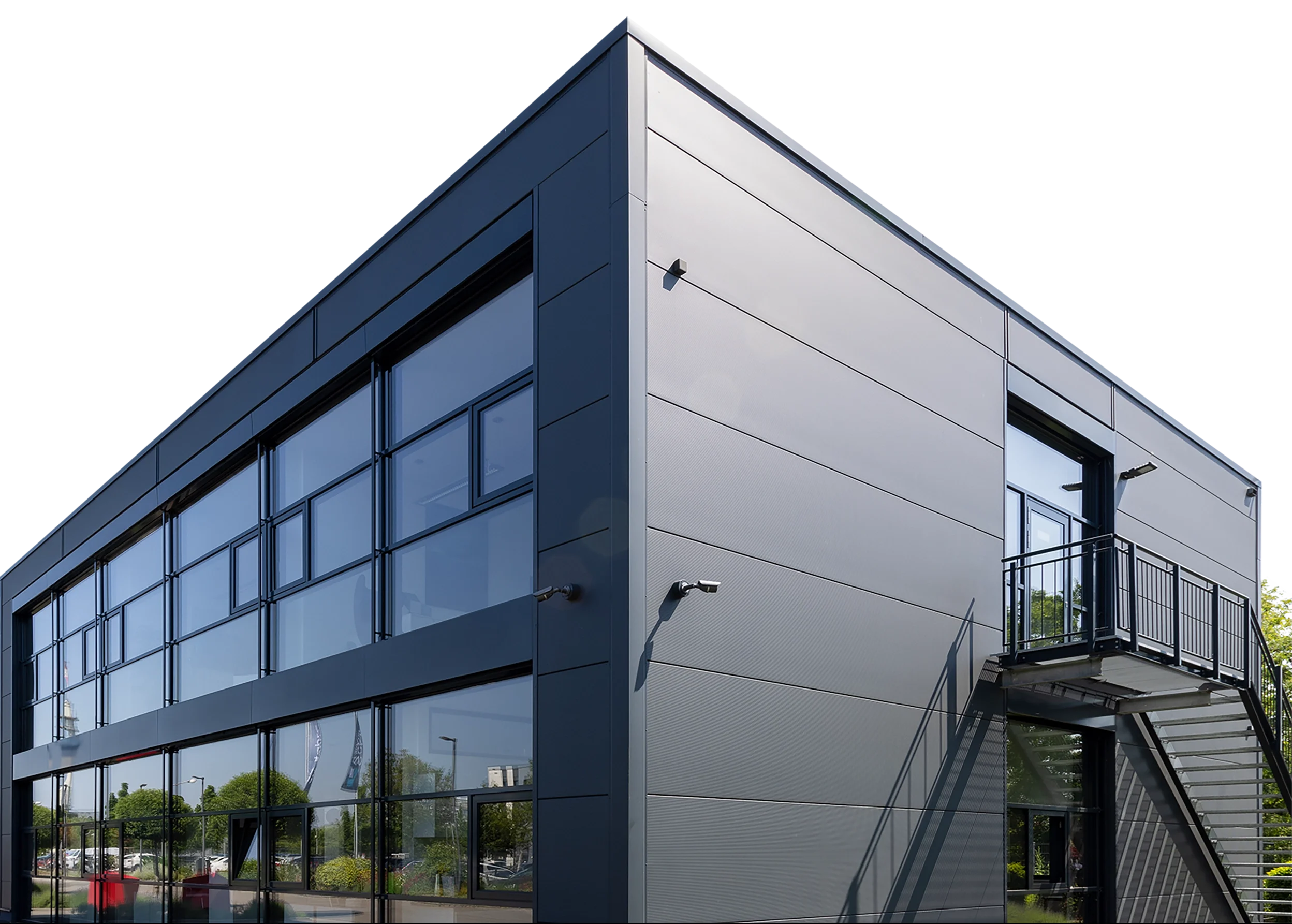

Schäfer Additivsysteme.

Wir stehen für Qualität. Innovation. Kundenfokus. Zuverlässigkeit.

Dr. Volker Schäfer

Gründer und CEO

Wir stehen für

Qualität. Innovation. Kundenfokus. Zuverlässigkeit.

Verbessern Sie die Perfomance und Qualität Ihrer Produkte – mit unseren innovativen Additiven.

Von der Verlängerung des Lebenszyklus, über die Steigerung der Performance bis zur verbesserten Verarbeitbarkeit bieten wir für jede Aufgabenstellung das passende Additiv. Gewissenhaft und handlungsschnell entwickeln wir perfekt auf Ihre Bedürfnisse zugeschnittene Produkte.

- Innovative und patentierte Produkte – seit über 20 Jahren.

- Umfangreiche und direkte Beratung – wir finden die passende Lösung.

- Umweltschutz und Nachhaltigkeit liegen uns am Herzen.

”Kompetente Beratung, umfassendes Know-How und das Streben nach Innovationen sind die Basis unseres Erfolgs.

Dr. Volker SchäferGründer und Senior Managing Partner

Zuverlässig und kompetent.

Wir stellen uns den stetig wandeln regulatorischen Herausforderungen der chemischen Industrie und arbeiten damit jederzeit konform mit dem gültigen Chemikalienrecht.

Sie wünschen weitere Informationen zu Einstufung und Kennzeichnung, Ökolabels, Lebensmittelkontakt und SVHC?

Wir finden auch für Sie die passende Lösung.

Tradition trifft auf Innovation.

Als innovatives Familienunternehmen steht neben unserem hohen Qualitätsanspruch die stetige Weiterentwicklung der eigenen Produkte und Prozesse im Vordergrund. Gleichzeitig ist der Schutz von Mensch und Umwelt für uns von größter Bedeutung. Dafür gehen wir Tag für Tag an unser Limit.

Nachhaltigkeit liegt in unserer DNA.

Die nächste Generation im Blick zu haben ist für uns als Familienunternehmen selbstverständlich. Unsere gesellschaftliche Verantwortung für den Klimaschutz nehmen wir daher besonders ernst. Das betrifft sowohl unsere Produktion als auch die Energieversorgung. So können wir beispielsweise durch unsere Photovoltaik-Anlage nahezu den gesamten Strombedarf des Jahres decken.

Unsere Produkthighlights.

155

21

51

Die Zukunft schon heute gestalten.

Unsere tägliche Arbeit zielt darauf ab ein besseres Morgen zu schaffen. Durch unsere hochwertigen Additive erhöhen wir die Lebensdauer und Qualität der Produkte unserer Kunden und tragen somit erheblich zur Ressourcenschonung bei. Dieses Verantwortungsbewusstsein treibt uns an.